Calendering Process

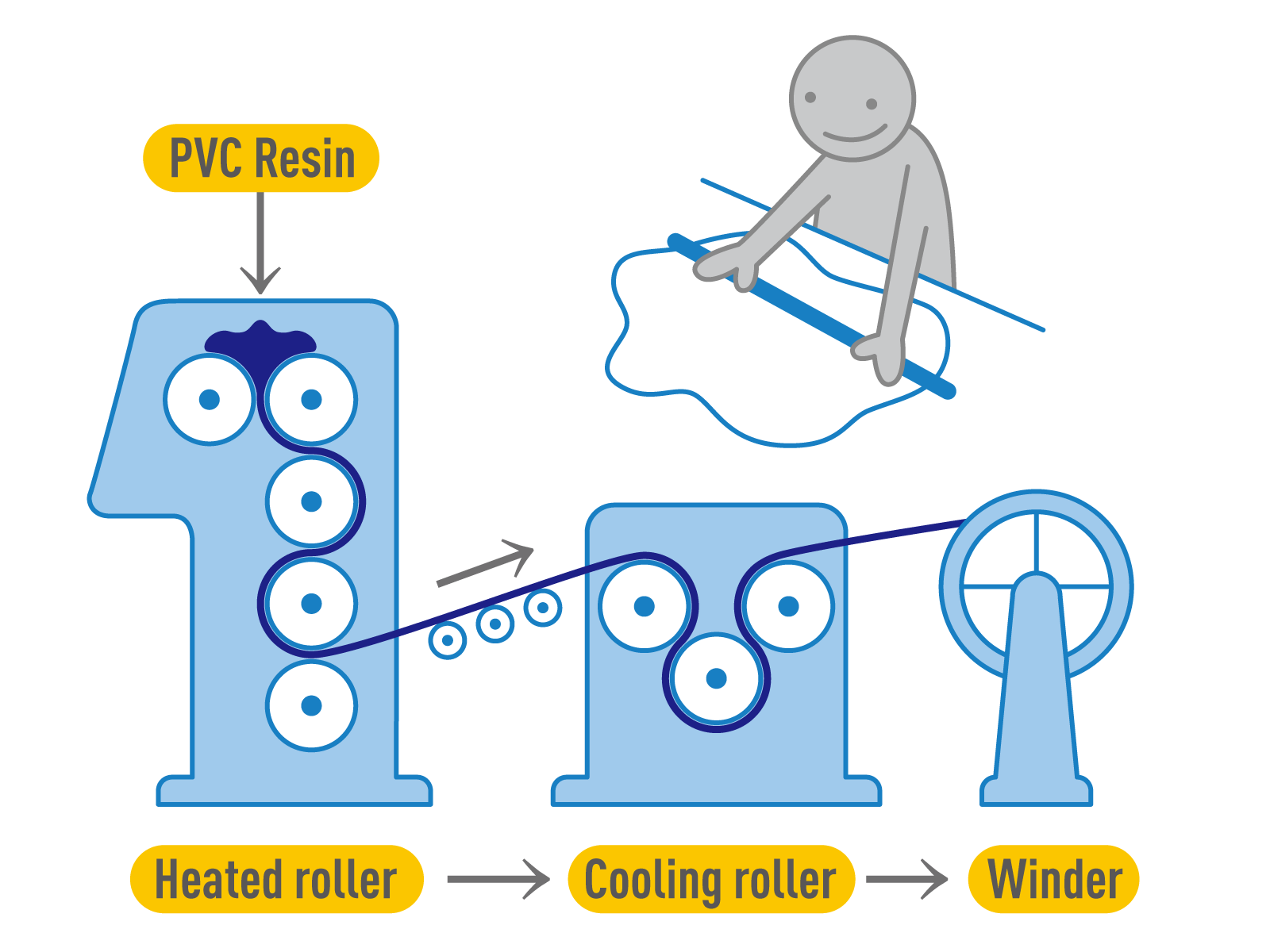

Calendering Process - Calendering is a continuous process involving the use of a series of heated rolls that are. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Web this video is aimed at school students of design and technology, and engineering. Learn about the history, types, and applications of. Web calendering process is a critical step in the production of libs.

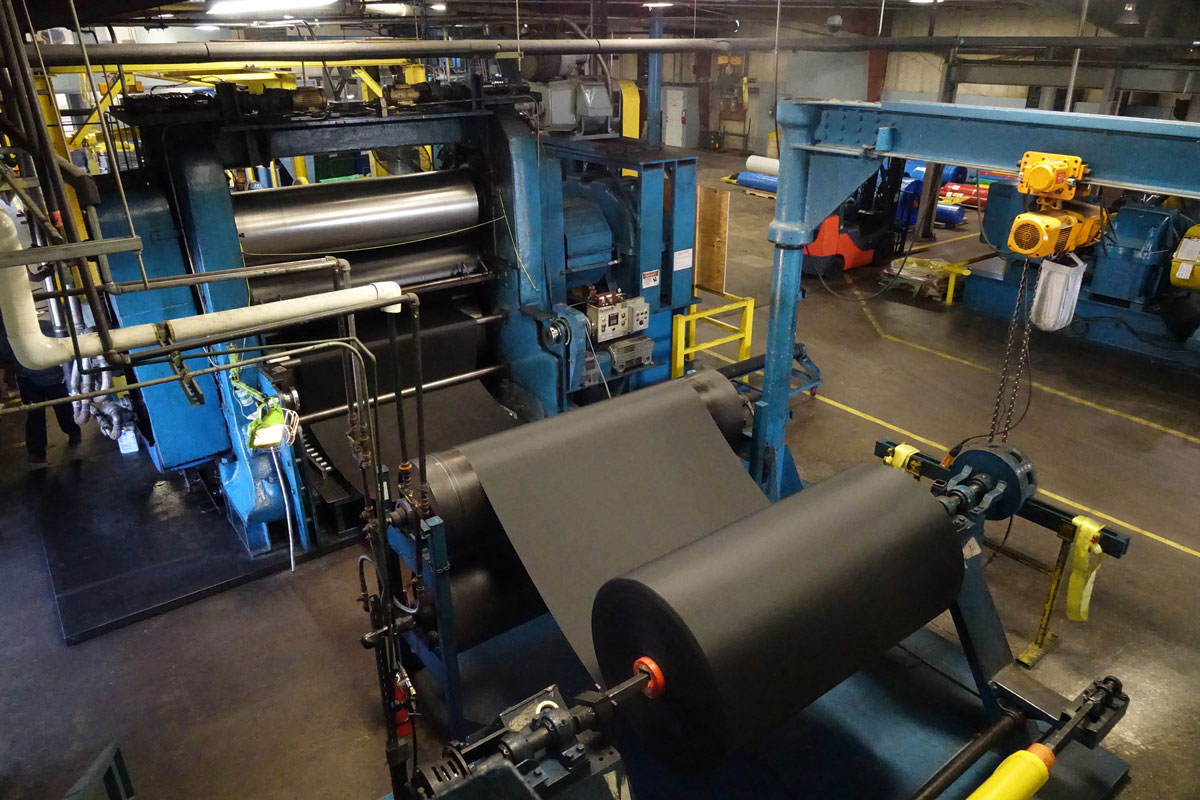

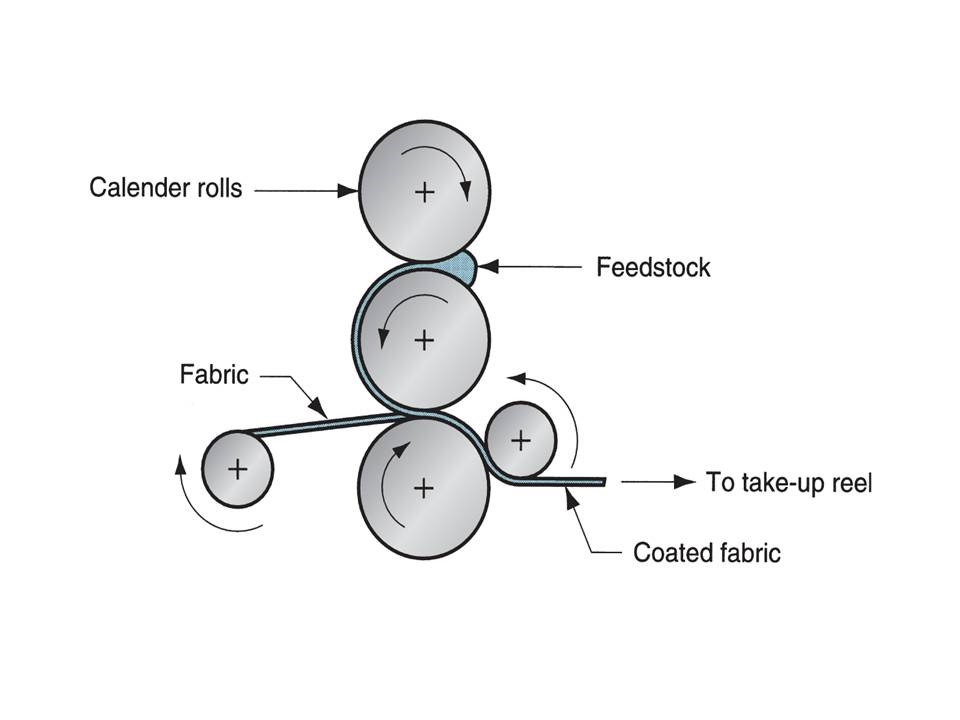

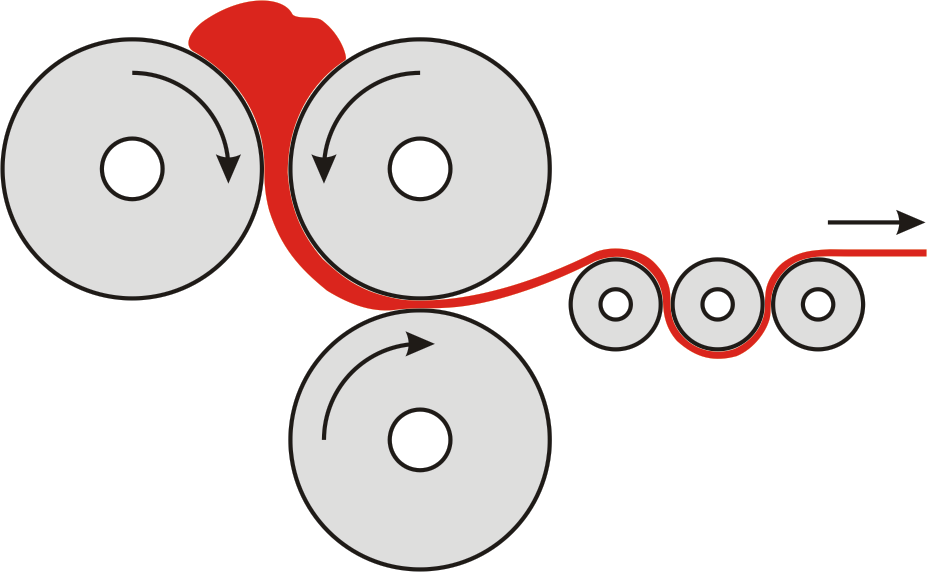

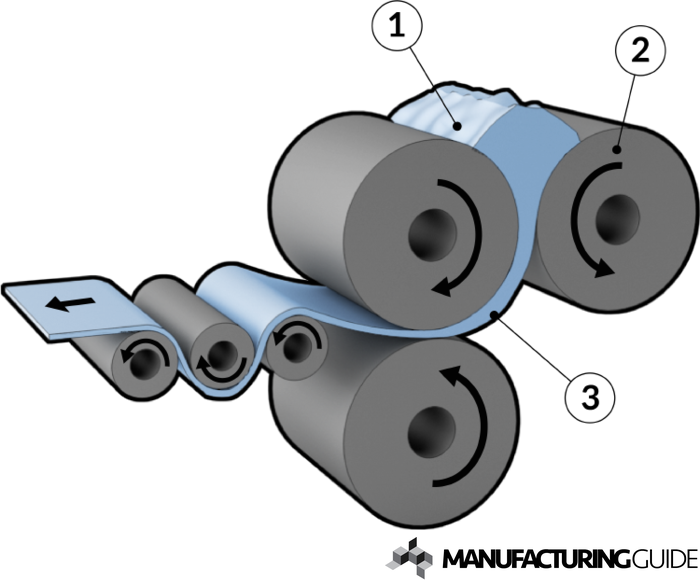

Web by lindas / april 25, 2023. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. Web a polymer mixture [1] is heated and fed between two rotating main calenders [2]. In preparation for calendering, the fabric is folded lengthwise with the front side, or face, inside,. Rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material. Calendering of textiles is a finishing process used to smooth, coat, or thin a material. Learn about the history, types, and applications of.

Schematic representation of the extrusioncalendering process of rPET

Web this video is aimed at school students of design and technology, and engineering. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as smoothness,.

CALENDERING|Manufacturing Process|About PVC|Vinyl Environmental Council

Learn about the history, types, and applications of. Web calendering process is a critical step in the production of libs. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as smoothness, gloss, and texture. Calendering is a continuous process involving the use of a series of heated.

Calendering Process.. YouTube

Find out the equipment, equipment, and benefits. It is the last step during. Web this video is aimed at school students of design and technology, and engineering. It is widely used in paper, textile, and plastic industries. The pulp is pressed to a rough thickness [3] and is then rolled by subsequent rollers to the.

How Calendered Vinyl Films are Made Hingst's Sign Post

Web calendering is a method of extruding plastic material between parallel rolls to form film or sheet. Learn about the history, types, and applications of. Calendering is a finishing process used on cloth and fabrics. Calendering enhances the contact between components to increase their bonding strength, electrical. Industries widely use the calendering process to create.

CSI Calendering, Inc Textiles

Web calendering is a manufacturing process of passing a single continuous sheet through a number of heated rolls to provide a smooth, glossy finish. In preparation for calendering, the fabric is folded lengthwise with the front side, or face, inside,. Finding the optimal compaction can require. Web calenders other processing approaches. Web this video is.

CALENDERING PROCESS CORPORATE TRAINING AND PLANNING CALENDERING

Learn about the history, types, and applications of. With textiles, fabric is passed under rollers at high temperatures and pressures. When carried out on a paper machine, it is called. Web the calendering process can improve polyester fabric's durability by increasing its strength and resistance to wear and tear. Calendering is used on fabrics such.

10 Facts About Calendering in Textile! Textile Property

It is widely used in paper, textile, and plastic industries. A calender is employed, usually to smooth, coat, or thin a material. Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as smoothness, gloss, and texture. The video covers calendering processes used to: Web calenders other processing.

6 Types Of Calendering Process In Textile Textile Property

Web calendering is a manufacturing process of passing a single continuous sheet through a number of heated rolls to provide a smooth, glossy finish. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. With textiles, fabric is passed between calender rollers at high.

Calendering for Filter Cloth Finishing Micronics Inc

Web the calendering process in textiles is a crucial step in fabric finishing that enhances properties such as smoothness, gloss, and texture. Finding the optimal compaction can require. Web calendering is a continuous process where melted plastic, paper, rubber or fabrics are squeezed between pairs of rollers. It is widely used in paper, textile, and.

Calendering Find suppliers, processes & material

It is the last step during. Calendering is a continuous process involving the use of a series of heated rolls that are. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. Learn about the factors that affect the processability, performance and cost of..

Calendering Process Web calenders other processing approaches. Web by lindas / april 25, 2023. Web calendering process is a critical step in the production of libs. Find out the equipment, equipment, and benefits. Here’s an overview of the.

The Video Covers Calendering Processes Used To:

Calendering is one method of making plastic sheets. Calendering is a finishing process used on cloth and fabrics. It is widely used in paper, textile, and plastic industries. Rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material.

Learn About The History, Types, And Applications Of.

Calendering is a continuous process involving the use of a series of heated rolls that are. Web calenders other processing approaches. Finding the optimal compaction can require. It is the last step during.

Web By Lindas / April 25, 2023.

Web this video is aimed at school students of design and technology, and engineering. Calendering enhances the contact between components to increase their bonding strength, electrical. Web calendering is a mechanical finishing process that alters the handle, surface texture and appearance of fabrics by compressing them between two or. Web the calendering process can improve polyester fabric's durability by increasing its strength and resistance to wear and tear.

Industries Widely Use The Calendering Process To Create Coated Fabrics, Thermoplastic Films, Plastic Sheeting, And Textile Fabrics To Procure The.

The pulp is pressed to a rough thickness [3] and is then rolled by subsequent rollers to the desired. Learn about the factors that affect the processability, performance and cost of. Web calendering is a method of extruding plastic material between parallel rolls to form film or sheet. Web calendering is a continuous process where melted plastic, paper, rubber or fabrics are squeezed between pairs of rollers.